- Home

-

Our Story

-

Back

- From the Principal

- Foundation and History

- Reconciliation Action Plan

- The Christian Brothers and Edmund Rice

- Aspiration Statement

- Leadership Team

- Prefects 2025/26

- College Crest and Song

- Frameworks

- Official Records

- Annual Reports

- Strategic Plan 2025 to 2029

- Edmund Rice Education Australia

- Employment

Our Story

- Learning

- Wellbeing

- Co-Curriculum

- Facilities

- Enrolment

- Parent Community

- News and Events

- Contact

Search

Staying active and healthy

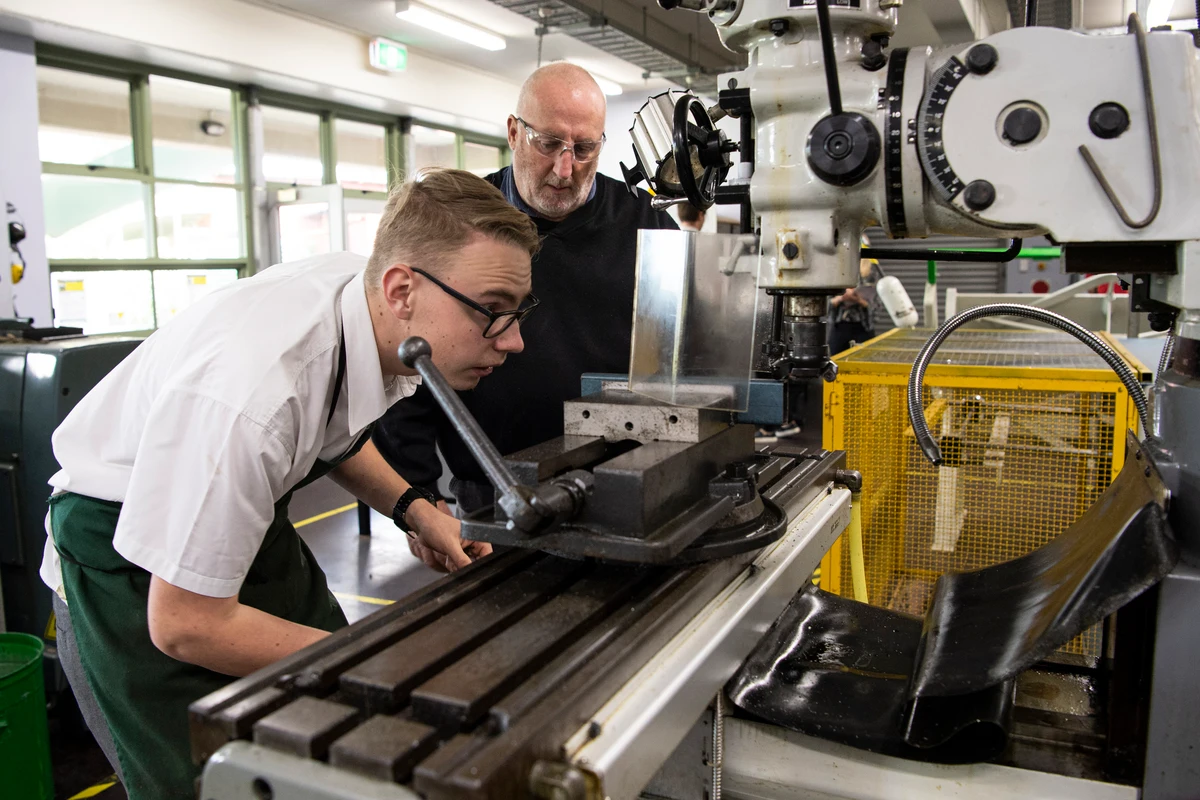

Metal Fabrication

Our Metal Fabrication pathway opens doors to industries that shape infrastructure, innovation, and opportunity.

Precision Craft. Purposeful Careers.

Based in our state-of-the-art workshop, students in Years 10–12 learn metalworking, welding, machining, CAD drafting, and safe site practices. With lathes, mills, plasma cutters, welding bays and more, the program delivers real-world skills and TRADE-RECOGNISED training. Graduates often step straight into apprenticeships, engineering roles, manufacturing careers or further study, turning their creativity and technical skill into lifelong success.

The equipment available in the workshop is as follows:

- 3 Lathes

- 2 Mills

- 2 Pedestal drills

- Electric guillotine

- Pan brake

- Cut off saw

- 4 Welding bays

- Cutting bay

- Hand tools

- Electric and battery drills

- Spot welder

- Angle grinders

- Nibbler

- 4 Mig welders

- 4 Inverter welders,

- Piped oxy-acetylene and argon

- Plasma cutter

The theory component of the Construction and Engineering Fabrication is carried out in an air conditioned classroom with networked computers, A3 laser printer, drawing tables and chairs, drawing boards and digital projector and sound system.